Tungsten & Molybdenum Sassan don Dasa Ion

Tungsten & Molybdenum Sassan don Dasa Ion

Muna ba da madaidaicin ion da aka dasa tungsten da kayan gyara molybdenum. Samfuran mu suna da girman barbashi mai kyau, ƙarancin dangi sama da 99%, kaddarorin injiniyoyi masu zafi sama da kayan tungsten-molybdenum na yau da kullun, kuma mahimmancin rayuwar sabis.

Waɗannan abubuwan dasa ion sun haɗa da:

•Electron watsi cathode garkuwa Silinda.

•allon kaddamarwa.

•Sansanin tsakiya.

•Farantin filament interrupter, da dai sauransu.

Bayanin Sassan Tsirrai na Ion

| Sunan samfuran | Sassan Gyaran Ion |

| Kayan abu | Pure Tungsten(W) / Molybdenum (Mo) |

| Tsafta | 99.95% |

| Yawan yawa | W: 19.3g/cm³ / Mo: 10.2g/cm³ |

| Matsayin narkewa | W: 3410 ℃ / Mo: 2620 ℃ |

| Wurin Tafasa | W: 5660 ℃ / Mo: 5560 ℃ |

| Lura: Gudanarwa bisa ga zane | |

Ion Implantation

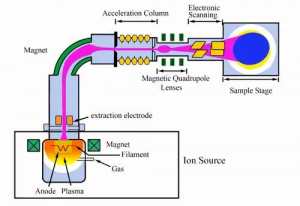

Ion dasawa shine muhimmin tsari a cikin samar da semiconductor. Tsarin dasa shuki yana gabatar da kwayoyin halitta na kasashen waje a cikin wafer don canza kaddarorin kayan aiki, irin su wutar lantarki ko tsarin crystal. Hanyar katako na ion ita ce tsakiyar tsarin shigarwa. A can, ana ƙirƙira ions, an tattara su, da kuma hanzarta zuwa ga wafer a cikin maɗaukakin sauri.

Lokacin da aka canza tushen ion zuwa ions plasma, ana ƙirƙirar yanayin aiki sama da 2000 ° C. Lokacin da aka fitar da katakon ion, yana kuma samar da makamashi mai yawa na ion. Karfe gabaɗaya yana ƙonewa kuma yana narkewa da sauri. Sabili da haka, ana buƙatar ƙarfe mai daraja tare da mafi girma yawan yawa don kula da jagorancin fitar da katako na ion da kuma ƙara ƙarfin abubuwan da aka gyara. Tungsten da molybdenum sune mafi kyawun kayan aiki.

Me yasa Zabi Tungsten & Molybdenum Materials don Abubuwan Dasa Ion

•Kyakkyawan juriya na lalata•Babban ƙarfin abu•Kyakkyawan halayen thermal

Suna tabbatar da cewa an samar da ions da kyau kuma an mayar da su daidai a kan wafer a cikin hanyar katako kuma ba tare da wani datti ba.

Amfaninmu

•Kayan albarkatun kasa masu inganci

•Babban fasahar samarwa

•Daidaitaccen CNC machining

•Ƙuntataccen kula da inganci

•Gajeren lokacin bayarwa

Muna haɓakawa bisa tushen tsarin samar da tungsten da kayan molybdenum. Ta hanyar gyaran hatsi, jiyya na alloying, vacuum sintering da zafi isostatic matsi sintering densification, na biyu hatsi tacewa da sarrafa mirgina fasahar, da high-zazzabi juriya, creep juriya da kuma sabis rayuwa na tungsten da molybdenum kayan an muhimmanci inganta.

Semiconductor Ion Fasaha Fasaha

Aiwatar da ion tsari ne da aka saba amfani da shi don doping da canza kayan semiconductor. Aikace-aikacen fasaha na ion implantation ya inganta haɓakar na'urorin semiconductor da haɗin gwiwar masana'antu. Don haka yin samar da haɗin gwiwar da'irori ya shiga zamanin manyan sikelin da ultra-large (ULSI).

Tuntube Mu

Amanda│Manajan tallace-tallace

E-mail: amanda@winnersmetals.com

Waya: +86 156 1977 8518(WhatsApp/Wechat)

Idan kuna son ƙarin cikakkun bayanai da farashin samfuranmu, tuntuɓi manajan tallace-tallacenmu, za ta ba ku amsa da wuri-wuri (yawanci ba fiye da 24h), na gode.